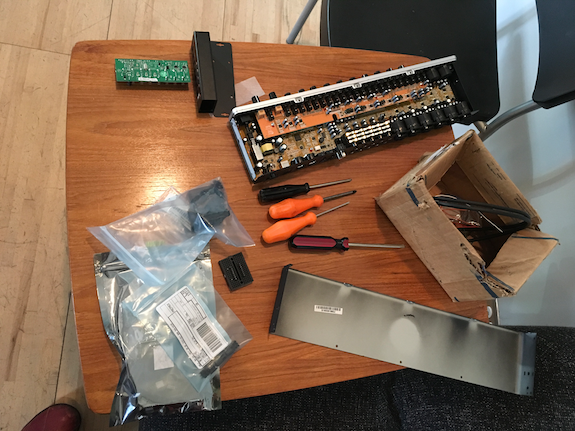

Need to wire 8 of those.

Need to wire 8 of those.

Finding silent motors

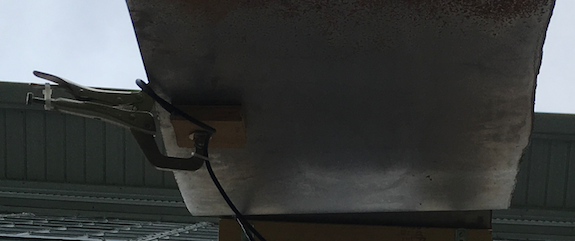

Some welding

Pulley are hard work with big tools, but we wont see them. That said, I started to really like them.

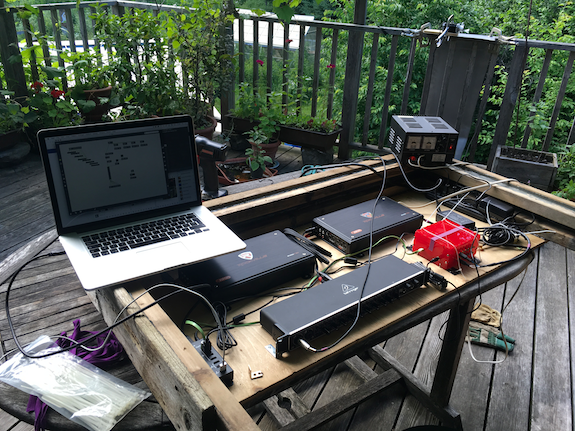

Finally not raining, test day

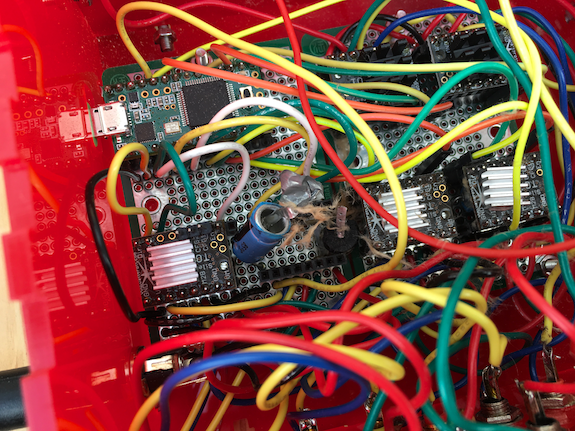

My setup. Box now nearly waterproofed, my Max/MSP patch half done, my silent MIDI to stepper motor interface finished and nicely running, amps running nicely, new sound interface is fine, everything is screwed in place, just need the right power supply for the amps instead of my maker space one.

Sandwiched piezo, 8 of them build wired

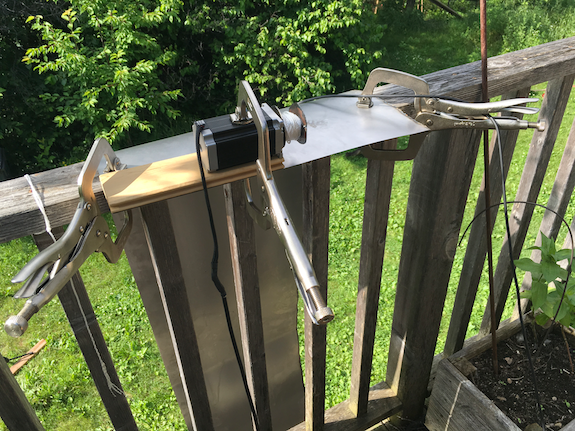

First pulley test with the full sized saw. Running better than expected.

Cut more musical saws today. Gloves for scale.

Setup day 2 first saw

Setup day 3 second and third saw

Setup day 4, technical stuff and rust

Setup day 5, technical test and composition

Setup day 6, composition and taking the cables up

Setup day 6, composition and taking the cables up

When things went wrong: rain and electronics do not go together

When things went wrong: exploded cap

When things went wrong: exploded cap

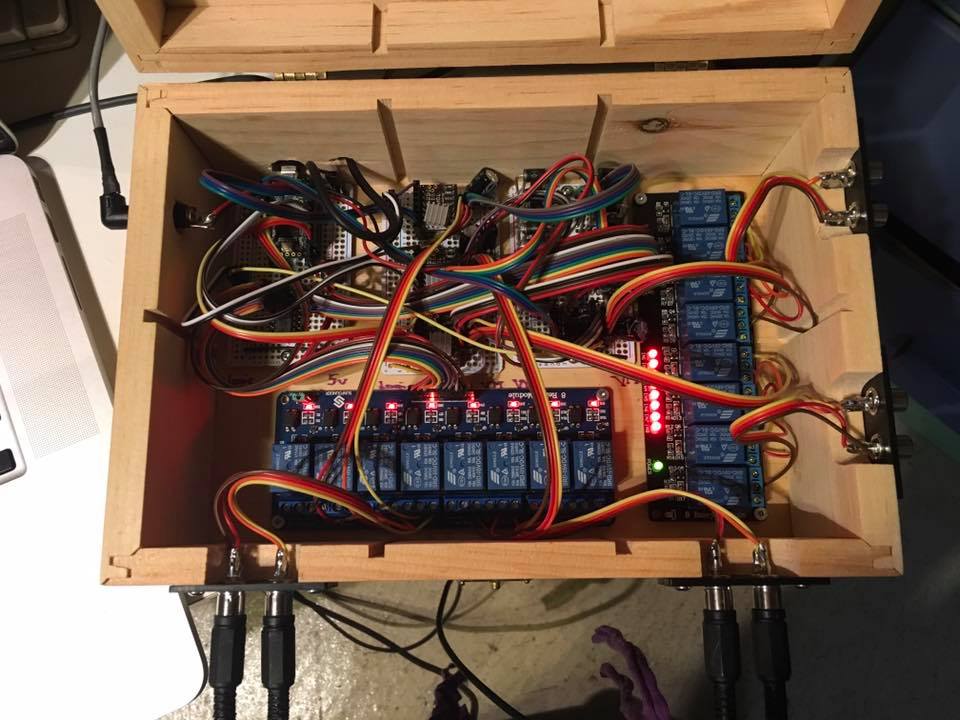

Solution: Better home made interface to avoid exploding caps with diodes and relays and yes, it is a tea box